With 25+ years of industry expertise, S&T Plastic Machine is the manufacturing venture of S&T Group, specializing in plastic injection molding machines.

Since 1996, we have supplied global machine tool brands to Indian manufacturing industries. In 2015, we expanded into manufacturing, delivering high-performance, reliable, and efficient plastic processing machineries, ranging from 60-800 Tonnages.

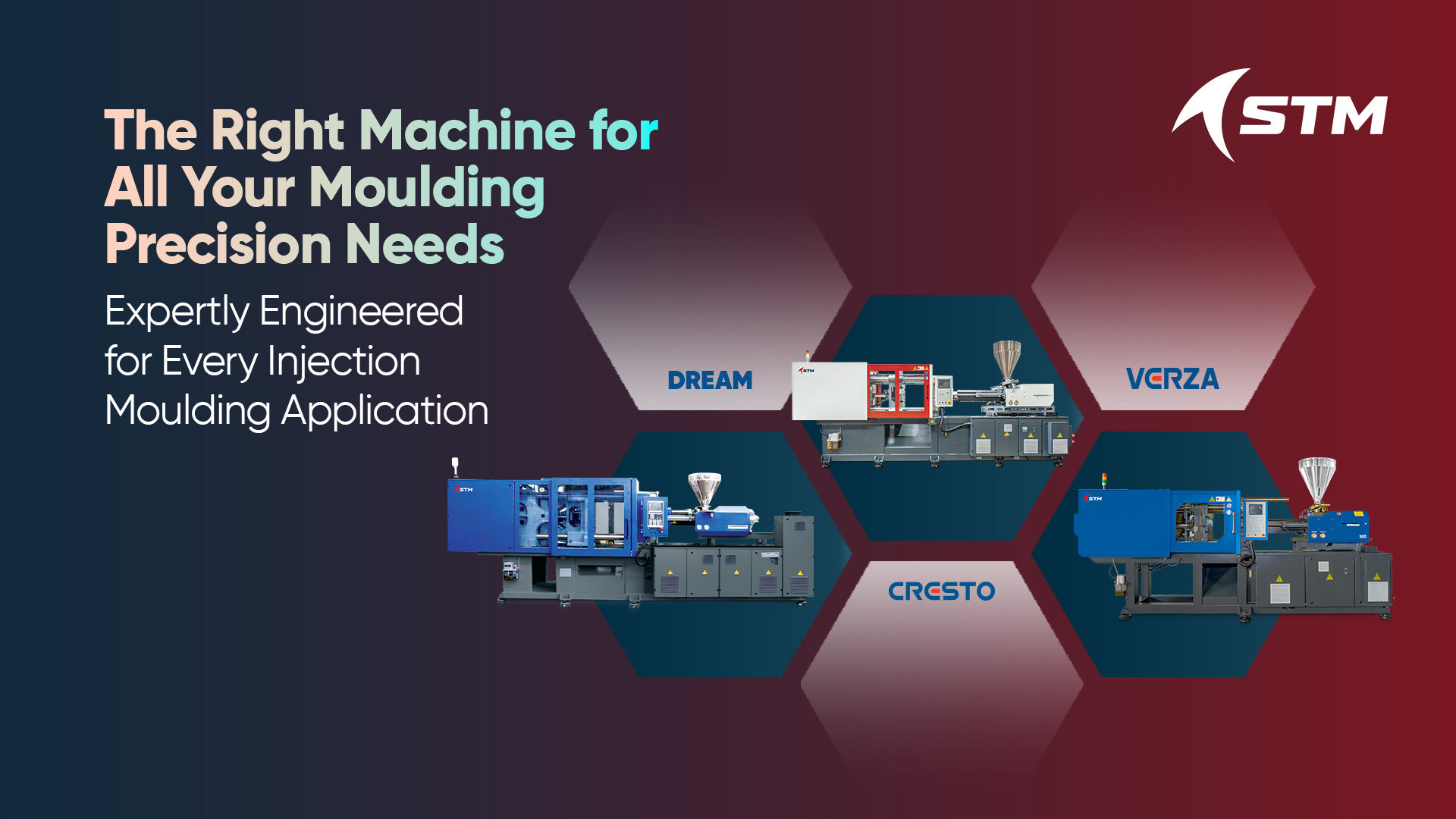

Committed to innovation and precision, we shape the future of plastic molding technology. Making World Class Technology Affordable to all .

0 +

Lorem ipsum dolor sit amet, consdter adipis elit, sed do eiusmod tempor incididu

0K

0 +

0K

As one of the major industries, the consumable plastic products industry provides many of the plastic products we use daily. Our injection moulding machines are engineered with precision to consistently deliver superior results every time, ensuring that manufacturers can produce high-quality everyday plastic products at low cost.

The packaging industry is growing at an unprecedented rate. With new market opportunities opening every day, there’s no doubt that this trend will continue. We are committed to assisting you in accomplishing your objectives by delivering the most advanced and high-speed plastic moulding solutions currently in the market.

The electronic components industry has always been fast-paced, ever-changing, and highly competitive. To keep up with the latest trends, you need to have a moulding solution that’s just as agile. We take great pride in knowing that our injection moulding machines are best-in-class in the electronic industry needs.

Comprehensive Customer Service & Support, including pre-installation guidance to professional setup, operator training, and preventive maintenance, we ensure seamless performance. Our expert team is always ready to assist, keeping your production smooth and efficient.

We manufacture world-class plastic machinery in India and offer them at affordable prices. Combining advanced technology with local expertise, we provide reliable solutions that help manufacturers compete globally without compromising on performance.

Our automation ready plastic molding machines enhance productivity by reducing manual intervention, optimizing cycle times, and ensuring consistent quality. S&T Plastic Machines help industries minimize downtime and maximize efficiency, making production faster, smoother, and smarter.

Engineered to serve automotive, consumer plastics, electronics, caps & closures, furniture, electronics, pipe fittings, industrial products, medical, mobile, packaging, thin wall moulding, white goods and household goods, our machines ensuring precision and reliability.

With a tonnage range from 60 to 800 tons, our Plastic moulding machines are ideal for small, medium, and large-scale production. Whatever your manufacturing needs, we have the right solution to keep your business growing and optimize production speed, reduce costs, and maintain superior quality.

PLASTO EXPO 2025 – Pune

08 Jan 2025

KPLEX 2024 – Bangalore

26 Apr 2024

INDPLAS 2025 – Kolkata

28 Feb 2025

PLASTFOCUS 2024 – New Delhi

01 Feb 2024

13 Jun 2025

Why Are More Manufacturers Upgrading To Advanced Injection Molding Machines In 2025? Get Insights Into Market Shifts, Tech Innovations, And Industry Expectations. Learn How These Trends Are Reshaping Production Across India.

Read More 🡥

05 Jun 2025

Looking For The Right Injection Molding Machine For Your Application? STM Offers A Versatile Range From 60T To 800T, Built For Performance And Precision. Explore How Our Machines Meet The Demands Of Industries From Automotive To Consumer Goods.

Read More 🡥

01 Feb 2025

One Such Game-changing Alternative Was Plastic (aka Polymers) — Once A Celebrated Marvel Of Modern Invention…

Read More 🡥